Overview

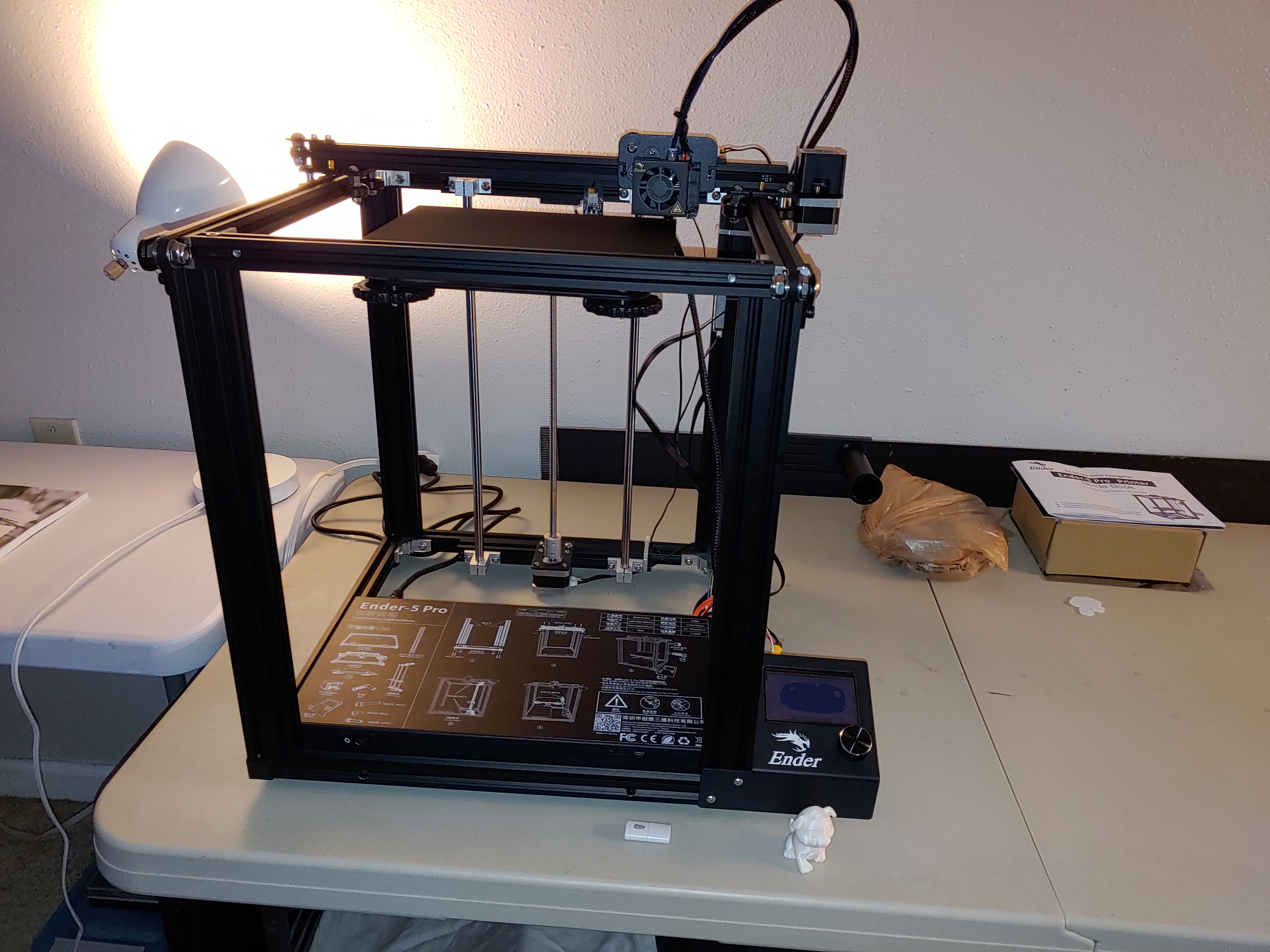

Ender 5 pro

This is mostly going to be a log of all the things i print, sometimes with small descriptions. I will also have an ideas section.

TPU Shoes

What is tpu?I understand tpu to be a type of rubber filament. I have never printed with it before. From what i've read it should work with the creality ender 5 pro i have without any special modificaitons, just a change in temperature.

What can you do with it that you can't do with pla or abs?TPU is basically like rubber, so it flexes a little bit, it's not as hard and brittle. The two things I want to do with it are:

1. remake my

car phone holder that is currently made from cardboard with tpu. Pla didn't work for that because it was too rigid, and the holder

needs to be a little bit flexible in the corners to hold the phone in, cardboard is flexible enough, the pla ones i printed were

not flexible enough, I think tpu would work great.

2. make tpu shoes. i think i actually have seen a pair at 5 below. I will try to remember to take a photo of them next time i'm there.

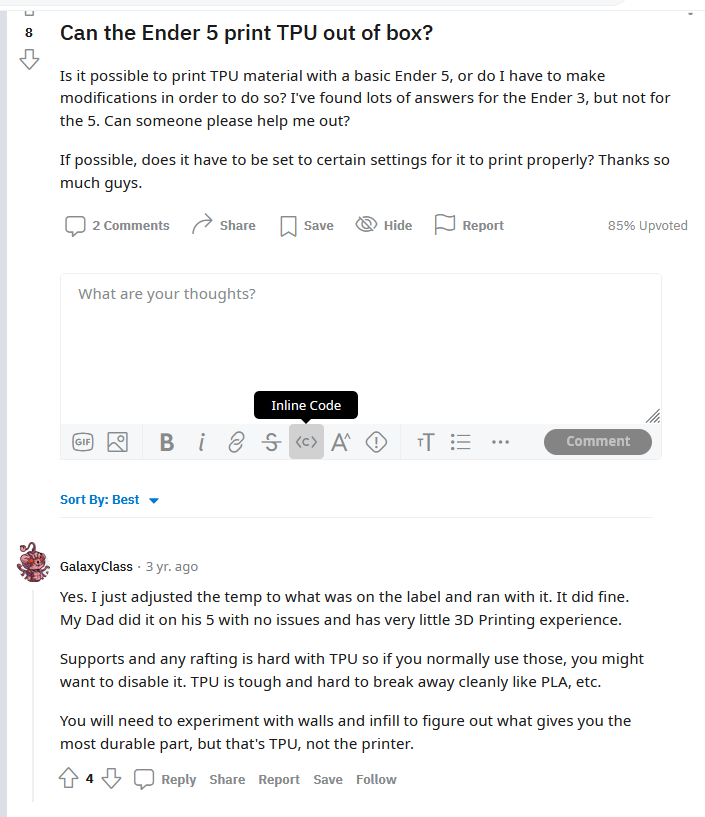

below are pictures of two reddit threads where people talk about this.

TPU Shoe Comment 1

This comment is what lead me to believe that I can print with the printer as is using tpu. Maybe these guys are lying, but this convinced me that it probably works, so i'm going to give it a try.

TPU Shoe Comment 2

This comment shows a picture of someone actually printing shoes, I'm pretty sure i could press the go button to make the printer print exactly the same pair of shoes that the op did. The other commenters of course argue about whether it's cost effective or not. Anyone who sees this site knows which side of that debate i'm on. i think we should be able to make our own stuff at our own houses, and we should do it at any cost, though i would point out that we might be able to make our own (possibly bioplastic from leaves) filament for free eventually.

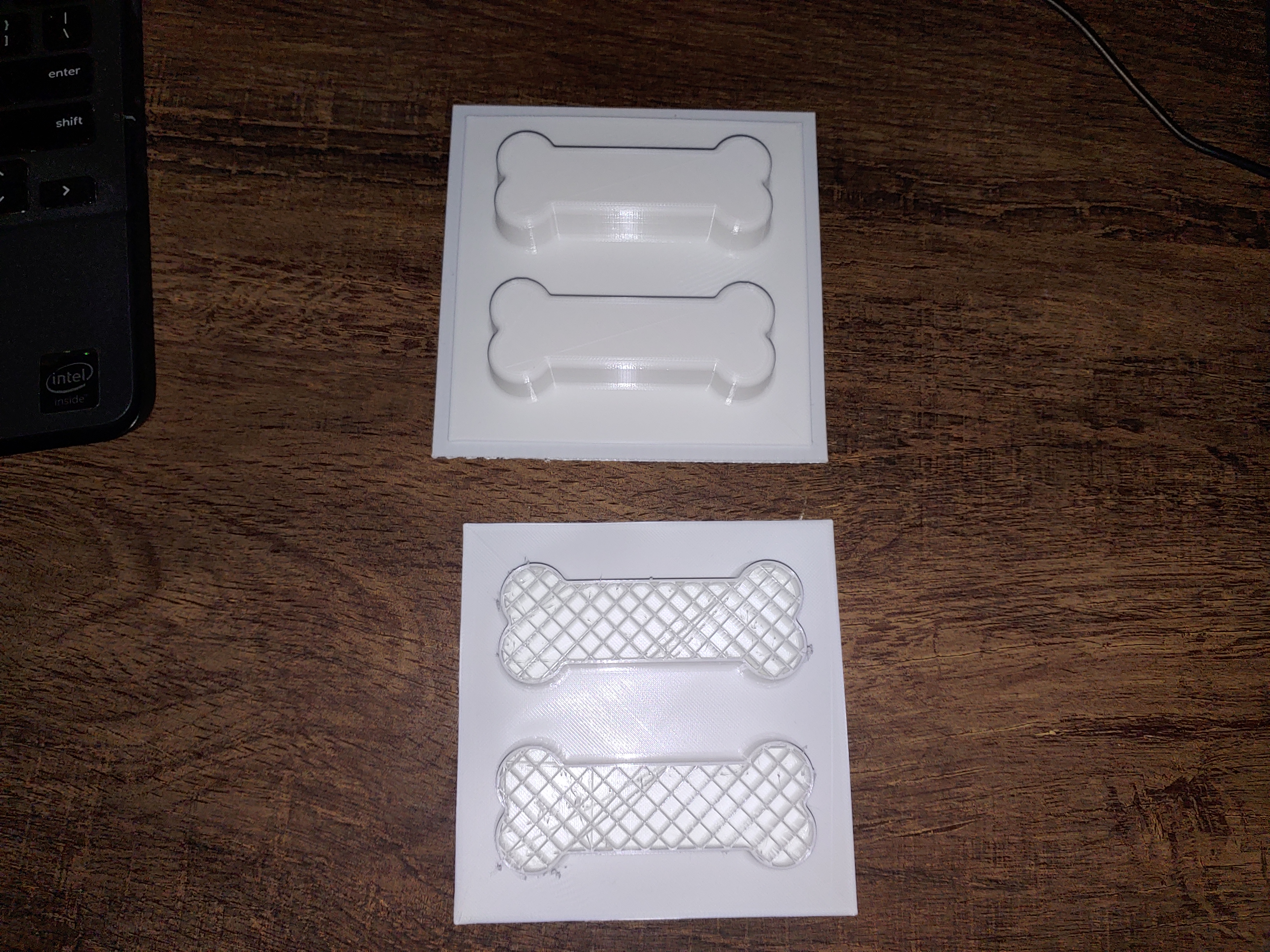

2nd Dog Bone Mold

The guy from craigslist texted me and asked me to print another dog bone. he said the incomplete mold from last time worked in a good way. I stopped the first print at 75% complete on purpose. I'm still going to print him another normal one too. I'm also going to measure the mm of his existing incomplete mold and see if my new 75% one is bigger or smaller. I'll let him know it's 75% complete so that he can keep that in mind when recording his future results.

update 8-30-2022

I printed a 75% mold and a 100% one again and met him outside again. He showed me the case for his project. This case used the molded plastic that he had made with the molds i 3d printed. The backplate of this plastic case was aluminum foil, there was a lot of artwork on the painted cardboard shell. The dogbones themselves appear to have lots of special vitamins and nutrients. He told me he would have a professional level website up soon and would send me the link. I gave the molds to him, he wanted to venmo me for it but i didn't have venmo so i guess he either couldn't pay me because he didn't have cash or forgot to pay me. I am planning to download venmo as a result of this. That's not what's important about this meeting though, what is important is that I told him about a couple of my ideas, the car phone holder and the lamp kit and let him know that i intend to get a patent on them and do the same thing he's doing. I told him about might try to approach the poetic case company eventually too. He told me he was a patent lawyer and offered to do a patent search for me for free. This is amazing. I plan to work on understanding and applying for a provisional patent along with finalizing both designs and printing better prototypes. I also am going to post both ideas here on this 3d printing page.

Dog Bone

Someone on craigslist wanted someone to 3d print a model for them. It turned out he wanted to use an advanced vacuum mold he had. He wanted to use this dog bone that I 3d printed for him as the mold. He seemed to intend to sell thousands of them. He paid me $25.00 for it.

download more here.